Pressure washers are a lifesaver when it comes to cleaning stubborn dirt and grime from outdoor surfaces. However, have you ever wondered how pressure washers work their magic?

The answer lies in the unloader valve – an essential component that helps regulate the water flow and pressure. But what exactly is an unloader valve, and how does it work?

In this full guide, we’ll dive into the nitty-gritty details of this crucial part of your pressure washer and explore its different types, uses, and benefits. So sit back, relax, and get ready to learn everything there is to know about how a pressure washer unloader valve works!

What Is A Pressure Washer Unloader Valve?

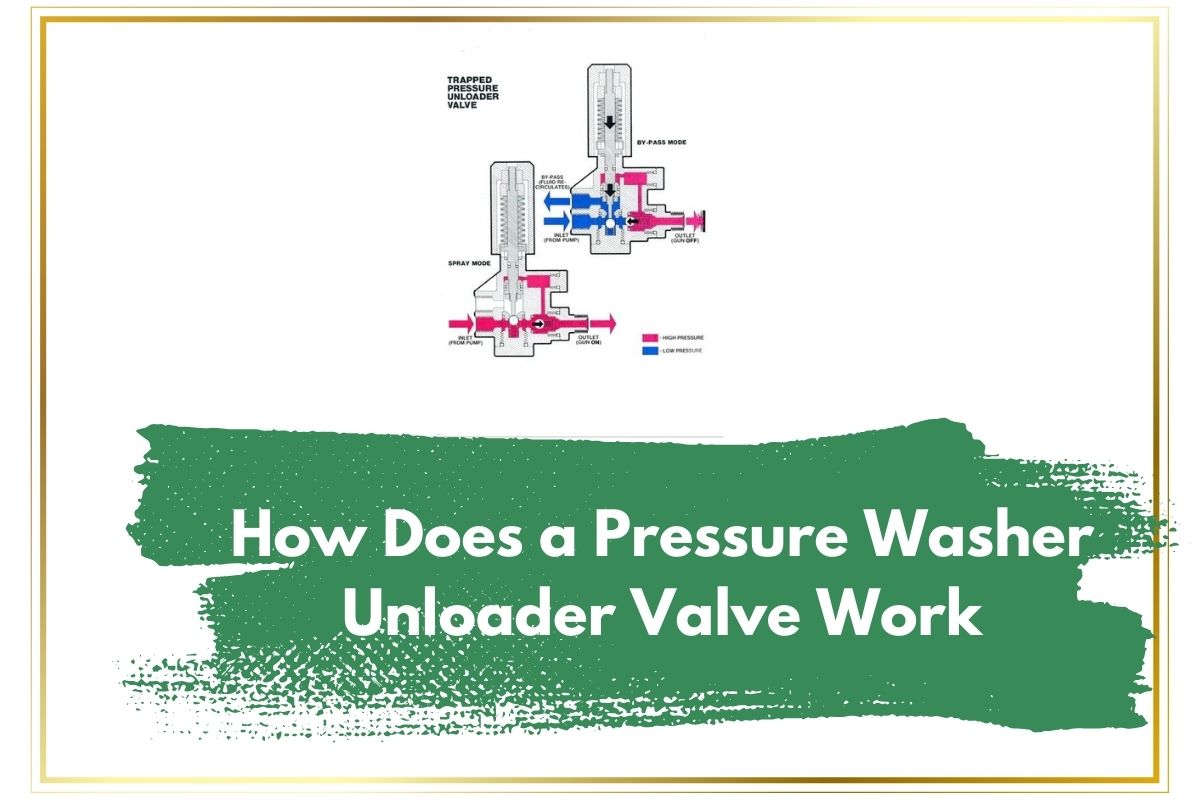

A pressure washer unloader valve is a device that helps regulate the water pressure and flow in your pressure washer. It works by diverting excess water back into the pump when there’s no demand for it, preventing the buildup of excessive pressure.

When you release the trigger on your spray gun, the unloader valve opens up and redirects the water back to its source. This process is crucial because without an unloader valve, constant high-pressure water flowing through your machine can cause damage to both your pump and spray gun.

Unloader valves come in different types depending on their mode of operation—some use flow control while others depend on pressure actuation. Regardless of which type you choose, having an unloader valve installed ensures that your machine operates smoothly without causing any damage or safety hazards.

Understanding what a pressure washer unloader valve is and how it works is crucial for maintaining optimal performance of your equipment while ensuring safe usage at all times.

read more-How to Adjust Pressure Washer Unloader Valve Like a Pro!

How Does A Pressure Washer Unloader Valve Work?

A pressure washer unloader valve is a crucial component of the machine that helps regulate water flow and pressure. The valve works by releasing excess water pressure from the pump, which prevents damage to both the pump and spray gun.

When you pull the trigger on your pressure washer wand, it releases a high-pressure stream of water. When you release the trigger, however, there’s nowhere for that pressurized water to go except back into the pump. This can cause serious damage if left unchecked.

That’s where the unloader valve comes in. The valve diverts some of this returning water away from the pump and back into either an inlet or another source such as a tank or barrel. By doing so, it reduces overall system pressure while maintaining continuous operation.

Different types of unloader valves work differently depending on their design and function.

Some operate via pressure actuation while others use flow control mechanisms to regulate water flow more precisely. Understanding how your particular model’s unloader valve works ensures optimal performance and longevity for your machine while also keeping you safe during usage.

What Are Types Of Pressure Washer Unloader Valves?

When it comes to pressure washer unloader valves, there are two main types: the Unloader Valve with Pressure Actuation and the Unloader Valve with Flow Control.

The first type, the Unloader Valve with Pressure Actuation, operates based on a preset pressure level. When this level is reached, it releases excess water through a bypass hose back into your unit’s water source. This type of valve is great for those who need consistent cleaning power and don’t want to worry about adjusting their machine regularly.

On the other hand, the Unloader Valve with Flow Control works by regulating the flow of water that passes through your unit. With this type of valve, you can adjust both your machine’s pressure and flow rate according to specific cleaning tasks. This gives users greater control over their cleaning jobs and ensures they get optimal results every time.

Both types of unloader valves have their benefits depending on what you’re looking for in a pressure washer. It’s essential to consider your needs before choosing which one will work best for you.

>Unloader Valve with Pressure Actuation

One type of pressure washer unloader valve is the one with pressure actuation. This type of valve works by using a spring-loaded plunger that pushes against the water flow when the trigger on the wand is released. As soon as this happens, it triggers a switch which then diverts the water back into the pump inlet and stops any further spraying from happening.

The benefit of this type of unloader valve lies in its simplicity. It’s easy to operate and maintain, making it an ideal choice for those who are new to using pressure washers or don’t want to deal with complicated parts.

However, there are also some downsides to consider. For instance, because these valves rely on spring tension, they can lose their effectiveness over time if not maintained properly. Additionally, they may not work well with certain types of pumps or hoses, which can lead to inconsistent performance and decreased efficiency.

If you’re looking for an uncomplicated solution that gets the job done without too much fuss, then a pressure actuated unloader valve might just be what you need!

>Unloader Valve with Flow Control

The Unloader Valve with Flow Control is a type of pressure washer unloader valve that regulates the amount of water flow through the system. It operates by sensing an increase in pressure and then redirecting excess water back to the inlet side of the pump.

This type of unloader valve allows for greater control over water flow, making it ideal for use in situations where precise cleaning is required. For example, when washing delicate surfaces or applying chemicals at specific rates.

One advantage of this type of unloader valve is that it reduces wear on other components within the pressure washer system. By regulating flow, it helps prevent damage caused by excessive pressure and increases overall lifespan.

Additionally, some models allow for adjustment to fine-tune flow rates based on application needs. This feature gives users even more control and flexibility during operation.

Choosing a pressure washer with an Unloader Valve with Flow Control can be beneficial for those who require precise cleaning capabilities and want to ensure longevity and efficiency from their equipment.

Why Do I Need A Pressure Washer Unloader Valve?

A pressure washer is a powerful tool that can make cleaning chores a lot easier and faster. However, it also requires proper handling to ensure safety and prevent damage. This is where the unloader valve comes in.

The unloader valve works by regulating the water flow and pressure inside the pump of your pressure washer. It prevents the buildup of excessive pressure that could lead to equipment damage or injury while still allowing optimal performance.

Safety is one major reason why you need an unloader valve for your pressure washer. With its ability to regulate water flow, it helps prevent sudden bursts of high-pressure water that can be dangerous not only for you but also for anyone nearby.

Another reason why you need an unloader valve is ease of use. By regulating the amount of water flowing through your machine, it reduces strain on both the operator and equipment, which means less fatigue and longer-lasting gear.

Investing in a quality unloader valve will help extend the life of your machine while ensuring safety during operation. Now that we’ve looked at why they are important, let’s explore what types exist!

>Safety

Safety is a major concern when it comes to using pressure washers, as the high-pressure stream of water can cause serious injury if not handled properly. One important safety feature of a pressure washer is the unloader valve.

The unloader valve helps regulate the flow and pressure of water in the pump by diverting excess water back into the inlet side of the pump. This prevents dangerous build-up in pressure that could lead to accidents or damage to equipment.

Without an unloader valve, there would be no way to safely release built-up pressure within the system. This means that if something were to block or obstruct the nozzle while you’re using your pressure washer, you could be at risk for serious injury from an unexpected surge in water pressure.

Having a functional unloader valve ensures that your machine operates safely and reduces potential risks associated with high-pressure cleaning tasks. Always make sure to follow proper safety protocols when handling any type of machinery, including wearing appropriate protective gear such as goggles and gloves.

>Ease of Use

One of the primary benefits of having a pressure washer unloader valve is its ease of use. Without an unloader valve, you would need to turn your pressure washer off every time you take a break or switch between different nozzles or attachments. This can be quite frustrating and time-consuming.

With a pressure washer unloader valve, however, all you have to do is release the trigger on the wand and let go of the pressure. The water will automatically circulate back into the pump through the unloader valve, allowing you to take breaks without turning off your machine entirely.

This feature makes it easier for beginners who may not know how to operate their machines properly yet. It also saves time for experienced users who want to work more efficiently.

Moreover, some models come with adjustable settings that allow users to control both spray patterns and water flow rates easily. These adjustments help make cleaning tasks even more accessible by enabling more precise targeting of dirt and grime while reducing overspray that could damage surfaces or waste water resources.

Having an unloader valve on your pressure washer ensures that using this powerful tool is as simple as possible while still achieving excellent results in less time than traditional methods ever could!

Why isn’t the pressure in my pressure washer increasing?

If you’re experiencing a lack of pressure in your pressure washer, there could be several possible reasons for this issue. One common cause is a clogged nozzle or spray tip, which can restrict the flow of water and reduce the overall pressure output.

Another potential factor to consider is whether the water supply is delivering enough volume and pressure to power your machine. You may need to check for any blockages or leaks in your hoses or connections that could be affecting the water flow.

It’s also worth checking whether there are any issues with your pump, such as worn-out seals, valves, or pistons that are decreasing its efficiency. A malfunctioning unloader valve can also lead to reduced pressure by allowing excess water to bypass the pump without building up sufficient force.

It’s important to make sure that you’re using an appropriate cleaning solution for your particular surface and application needs. Using too strong a detergent mixture can create thick foam that reduces water flow and lowers overall performance.

By troubleshooting these possible causes one at a time, you should be able to identify and fix what’s causing low-pressure issues with your pressure washer.

What causes a pressure washer to malfunction?

There are several reasons why a pressure washer might malfunction. One of the most common causes is a clogged or dirty nozzle, which can restrict water flow and reduce pressure. This can be easily fixed by cleaning or replacing the nozzle.

Another cause could be a damaged pump seal, which allows water to leak out and reduces the efficiency of the machine. Regular maintenance checks can help prevent this issue.

A faulty unloader valve can also cause problems with a pressure washer’s performance. If it is not functioning properly, it may result in low water pressure or even damage to the pump itself.

In addition, using incorrect detergents or adding them directly into the machine instead of applying them through an appropriate dispenser can also lead to malfunctions and damage over time.

It’s important to note that proper usage and regular maintenance are key factors in preventing malfunctions from occurring in your pressure washer.

When a pressure washer pump freezes, what happens?

When a pressure washer pump freezes, it can be a major problem. Freezing temperatures can cause the water inside the pump to expand and potentially damage the internal components.

One of the main signs that your pressure washer pump has frozen is if you turn on the machine and there is no water flowing from the spray gun. This could mean that ice has formed within the pump, preventing any water from passing through.

If you suspect that your pressure washer pump may have frozen, it’s important to take action immediately. Continuing to use a frozen pump can cause further damage and potentially result in costly repairs or replacement.

To prevent freezing, it’s recommended to store your pressure washer in a dry and warm location during colder months. You should also ensure that all water has been drained from the machine before storing it away.

In summary, when a pressure washer pump freezes, it can cause significant damage and prevent proper functioning of your equipment. Taking preventative measures such as proper storage during colder months can help avoid this issue altogether.

Conclution

To sum up, a pressure washer unloader valve is an essential component of your pressure washing system. It helps regulate the water flow and ensures that the pump doesn’t get damaged due to excessive pressure. By understanding how it works and the different types available, you can make an informed decision on which one will work best for you.

Remember that safety should always come first when using a pressure washer. Always follow proper operating procedures and wear appropriate protective gear such as eye protection and gloves.