Are you frustrated with your pressure washer soap injector not working properly?

You’re not alone! Many homeowners and professionals face this issue, often turning a simple cleaning task into a tedious chore. But worry no more! In this comprehensive guide, we’ll walk you through the steps to identify and fix common problems related to your pressure washer’s soap injector. With our tips and tricks,

you’ll get back to enjoying the convenience of efficient soap dispensing in no time. So, let’s dive right in and tackle those pesky issues that are keeping your pressure washer from performing at its best!

How do you fix a chemical injector on a pressure washer?

First and foremost, it is crucial to check your pressure settings. A common reason for a soap injector not working properly is the pressure washer operating at too high or low of a setting. Ensure you’re using the recommended pressure level based on your specific model.

Next, examine the supply valve’s pressure. If there isn’t enough water flow, the chemical injector may struggle to draw soap into the system effectively. Make sure that both your water source and hose connections are functioning correctly and supplying adequate water volume.

Another essential aspect to consider is using the right nozzle for soap application. Most models require a low-pressure nozzle or specific “soap” nozzle which allows proper suction from the chemical injector while in use.

If you have followed these measures, but issues persist, test for blockages within your injector assembly. Dirt or debris buildup can hinder its performance; therefore clean all components involved in ensuring smooth operation.

Give attention to maintaining a clear path through your soap injection system by cleaning out any clogs you might find throughout regular inspections and maintenance routines regularly.

Check your pressure settings

Before checking your pressure washer’s soap injector, it is important to ensure that the machine’s pressure settings are appropriate. The correct pressure setting will help to ensure that the chemical injector works effectively.

To check your pressure settings, consult your user manual for instructions on how to adjust them. You can also use a pressure gauge to measure the water pressure coming out of your machine.

Make sure that you set the right amount of PSI (pounds per square inch) or GPM (gallons per minute) depending on what type of cleaning task you are doing. Remember, too much or too little water flow can impact both cleaning efficiency and effectiveness.

If you’re using a higher-pressure nozzle than necessary, this could be causing problems with your chemical injector as well. Using a low-pressure nozzle will allow for better suction and mixing of chemicals in with the water stream.

By ensuring that your pressure settings are correct before attempting any other fixes on your pressure washer’s soap injector, you’ll be able to troubleshoot more efficiently and get back to deep-cleaning surfaces quickly!

Check the supply valve’s pressure

When your pressure washer soap injector is not working, one of the things you need to check is the supply valve’s pressure. The supply valve is responsible for regulating water flow into the system and can cause problems with chemical injection if it’s not functioning correctly.

To start checking your supply valve’s pressure, turn off your pressure washer and disconnect all hoses from it. Locate the supply hose that connects to the unit and attach a water-pressure gauge to this point.

Now turn on your garden hose to full blast to see what kind of reading you get on the gauge. If your gauge reads less than 20 psi, then there may be an issue with low water flow causing issues with chemical injection.

If this problem persists after testing multiple times or trying different nozzles, then it may be necessary to clean out any debris or obstructions in both ends of the hose as well as inside filters located within fittings between hoses themselves!

Make sure to use the right nozzle

Using the right nozzle is crucial when it comes to pressure washing. The nozzle determines the size and shape of the water spray, which in turn affects the cleaning power of your pressure washer. Using a nozzle that’s too small can damage surfaces, while using a nozzle that’s too big can reduce cleaning efficiency.

Before you start pressure washing, make sure to read your manufacturer’s manual to determine what nozzles are recommended for your machine. Most machines come with interchangeable nozzles that produce different spray patterns such as 0-degree, 15-degree, 25-degree and 40-degree angles.

The most commonly used nozzles for pressure washing are the 25-degree and 40-degree angle nozzles since they offer a good balance between cleaning power and surface safety. If you’re dealing with tough stains or heavily soiled areas, opt for a narrower angle like a 0- or 15- degree nozzle but use them with caution as they can cause damage if not used correctly.

It’s also important to regularly check your nozzles for any damages or blockages before starting any job. Damaged or blocked nozzles can cause low-pressure output leading to inefficient cleaning results.

Using the correct nozzle is vital when it comes to effective pressure washing. Always refer back to your manufacturer’s manual and ensure each job requires an appropriate sized-nozzle suitable for specific tasks at hand!

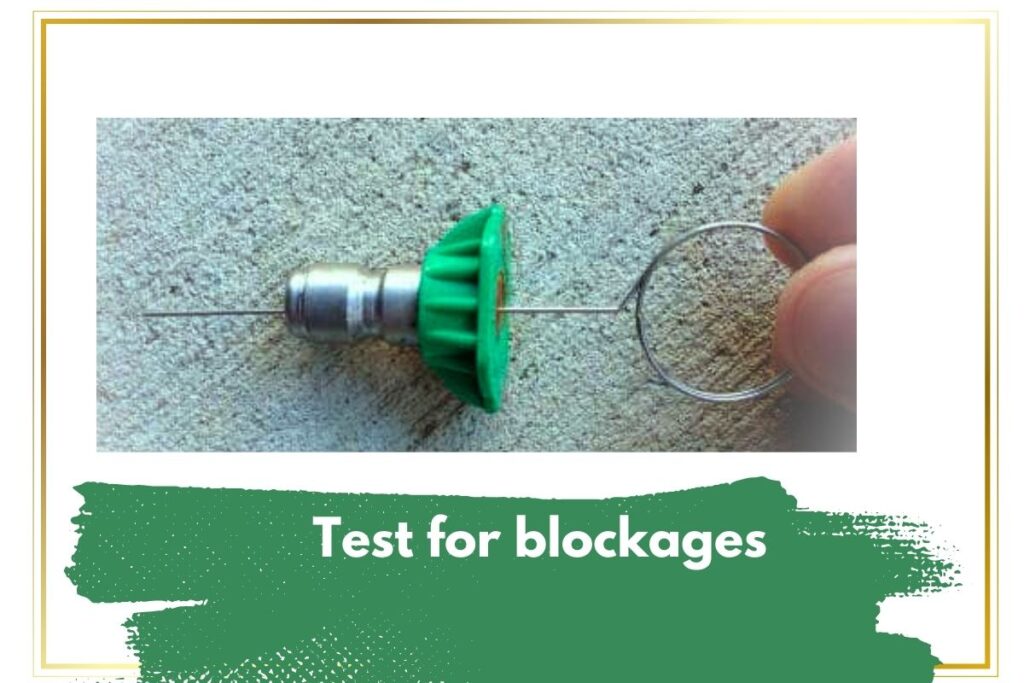

Test for blockages

To test for blockages in your pressure washer’s soap injector, start by disconnecting the hose and wand from the machine. Then, remove the chemical filter and inspect it for any debris or clogs. If you notice any buildup on the filter, clean it thoroughly before reassembling.

Next, turn on your pressure washer and engage the soap dispenser. Listen carefully to hear if there is a suction sound coming from the injector line. If you don’t hear anything, this could indicate that there is a blockage preventing proper flow.

Another way to check for blockages is to insert a thin wire or needle into the injector nozzle to see if there are any obstructions present. Be sure not to damage the nozzle while doing so.

It’s important to regularly test for blockages in your pressure washer’s soap injector because buildup can lead to decreased performance and even damage over time. By following these steps, you can ensure that your equipment operates at its highest level of effectiveness.

Clear your injector

If you’ve checked for blockages and your pressure washer soap injector is still not working, it’s time to clear the injector. The first step is to turn off the pressure washer and release any pressure by squeezing the trigger gun.

Next, remove the chemical hose from the inlet fitting of the injector. Use a small needle or wire to clean out any debris that may be blocking the orifice in both ends of the soap injector.

Once you’ve cleared out any blockages, reattach all hoses and fittings securely before turning on your power washer. Test your soap dispenser again by squeezing the trigger gun multiple times to ensure proper operation.

It’s important to note that if clearing your injector doesn’t solve your problem, there may be an issue with other components such as valves or nozzles. Always refer back to your owner’s manual for further troubleshooting steps or contact a professional for assistance.

What Is A Pressure Washer Soap Dispenser?

A pressure washer soap dispenser, also known as a chemical injector, is an essential component of a pressure washing system. It is responsible for injecting detergent or soap into the water stream to enhance cleaning efficiency. The soap dispenser typically has two valves – one for water and another for detergent- which work together to create a blend that cleans tough stains.

Pressure washer soap dispensers come in different types and designs based on the brand and model of your machine. Some are integrated into the unit’s structure while others can be attached externally via hoses. They may also have adjustable settings to regulate how much detergent gets mixed with the water.

The use of soap helps loosen dirt and grime from surfaces like cars, driveways, patios, decks, among others that require thorough cleaning beyond what plain water can do. Understanding what a pressure washer soap dispenser is and how it works is crucial for optimal performance during cleaning tasks.

Why Would A Pressure Washer Need Soap?

A pressure washer is a tool that uses high-pressure water to clean surfaces effectively. However, sometimes just using water isn’t enough to get rid of all the dirt and grime on your surfaces. That’s where soap comes in.

Using soap with your pressure washer can help you remove stubborn stains and grease from various surfaces such as cars, driveways, decks, and more. Soap helps break down the dirt particles so they can be easily washed away by the pressurized water.

Additionally, using soap can also help protect your surfaces from damage caused by high-pressure water. The soap creates a protective barrier between the surface and the water stream which reduces any potential damage that may occur.

It’s crucial to note that not all soaps are created equal when it comes to pressure washing. Some soaps are specifically designed for use with pressure washers while others could potentially cause damage or clog up your system.

Adding soap to your pressure washing routine gives you an extra boost in cleaning power while providing protection against potential surface damages caused by high-pressure streams of water.

Why Does Your Pressure Washer Soap Injector Not Working?

There are a few reasons why your pressure washer soap injector may not be working properly. One common issue is that the inlet filter could be clogged with debris, preventing the flow of water and detergent. This can happen over time if you use hard water or if there’s debris in your water source.

Another reason could be a faulty chemical injector valve. If this component is damaged or worn out, it won’t allow for proper mixing of the detergent and water, resulting in little to no foam being produced during cleaning.

Additionally, using an incorrect nozzle size can also cause issues with your soap dispenser. A nozzle too small will increase pressure but decrease flow rate while a larger one will do the opposite.

Low-pressure settings on your pressure washer could prevent proper operation of the chemical injection system as well. Make sure to adjust both high and low-pressure settings accordingly before attempting any cleaning tasks.

By understanding these potential causes, you’ll have a better idea of how to troubleshoot and fix any issues with your pressure washer’s soap injector.

How To Maintain Your Pressure Washer

Maintaining your pressure washer is crucial to keep it working at its best. Here are some tips on how to maintain your pressure washer.

First, always check the oil levels before starting your machine. Make sure that there is enough oil in the engine and change it regularly as recommended by the manufacturer.

Second, clean or replace air filters frequently. A dirty air filter can cause damage to the engine and reduce performance.

Third, inspect hoses for signs of wear or damage and replace them if necessary. Leaks and cracks can significantly reduce water flow and pressure leading to poor cleaning results.

Fourth, always store your pressure washer properly after use. Drain all fluids from the machine, including gasoline and detergent solutions, then store it in a dry place away from direct sunlight.

Follow manufacturer’s instructions for any additional maintenance requirements such as spark plug replacement or pump maintenance.

By following these simple steps you will ensure that your pressure washer remains reliable for years to come!

Conclusion

To sum up, if you are facing issues with your pressure washer soap injector not working, the above-mentioned tips and tricks can help you troubleshoot and fix the problem. From checking the pressure settings to clearing blockages in the chemical injector, a little bit of maintenance can go a long way in ensuring that your pressure washer works smoothly.

It is crucial to follow regular maintenance measures like cleaning or replacing filters and using proper detergents to avoid clogging of the chemical injector. By doing so, you can prevent costly repairs down the line and keep your equipment running efficiently for years to come.

Remember that proper care and attention will ensure that your pressure washer has an extended lifespan while providing optimal performance every time. So, invest some time in maintaining it well today!